Wonderful appearance, the rise of national goods! To true precision instruments successfully released atomic force microscope series products!

Release time:

2024-07-02

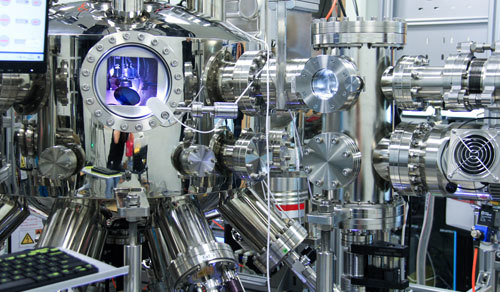

On May 24-26, at the first "Scientific Instrument Developers Conference", the atomic force microscope series products independently developed by Zhizhen Precision Instruments were released! Products released this time include multi-function atomic force microscopes (AtomicaPrecision) and wafer-scale atomic force microscopes (Wafer Mapper-M).

Two-dimensional ferromagnetic materials have a wide range of potential applications in the fields of electronics, spintronics and magnetic storage due to their thin-layer structure and unique physical properties. The research of these materials is very important to promote the development of related technologies. The low-temperature strong-field micro-laser Kerr microscopic imaging system has unique advantages in the study of two-dimensional ferromagnetic materials.

Recently, Professor Xu Xiaohong and Professor Xue Wuhong of Shanxi Normal University have cooperated to carry out experimental research using the low-temperature strong-field micro-area laser Kerr microscopic imaging system independently developed by Zhizhen, and reported the sub-millimeter controllable preparation of two-dimensional ferromagnetic Cr5Te8 material, and found that the material has a magnetization reversal process controlled by domain wall nucleation and non-monotonic magnetic field related magnetoresistance, the research results, entitled "Controlled Growth of Submillimeter-ScaleCr5Te8 Nanosheets and the Domain-wall Nucleation Governed Magnetization Reversal Process", were published in the top international journal Nano Letters(SCI TOP, impact factor: 10.8).

Original paper:https://pubs.acs.org/doi/10.1021/acs.nanolett.3c04200

Submillimeter two-dimensional Cr5Te8 and its magnetic domain evolution and non-monotonic magnetoresistance

The low-temperature strong-field micro-area laser Kerr microscopic imaging system contributes to this research in the following aspects:

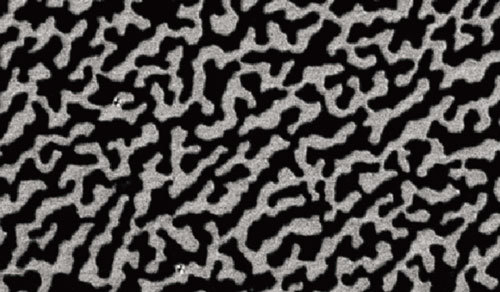

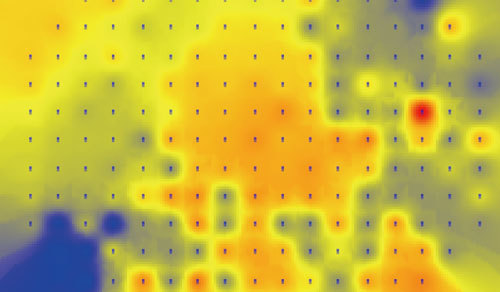

1. Direct observation of the magnetization reversal process: A high-resolution Kerr microscope combined with a vacuum refrigeration bench was used to conduct a comprehensive study of the magnetization process of Cr5Te8 nanosheets. By first saturating one direction of the sample with a large magnetic field, and then applying a magnetic field in the opposite direction, the detailed process of magnetization reversal was observed.

2. Analysis of magnetic domain structure and evolution: Kerr microscopy is used to capture the magnetic domain evolution process of Cr5Te8 nanosheets, including the propagation of magnetic domain walls. The article points out that by gradually increasing the magnetic field, the magnetic domain wall propagation in the process of magnetization reversal is clearly captured.

3. Minimum field strength determination of magnetic domain wall propagation: By Kerr microscope observation, it was determined that the minimum field strength required for magnetic domain wall propagation in the sample is about 30-45 mT, regardless of which of the two magnetization directions.

4. Understanding of magnetization reversal mechanism: The observation results of Kerr microscope reveal the leading role of domain wall nucleation in controlling the magnetization reversal process, which provides an important reference for optimizing the performance of related equipment (such as efficiency, stability, etc.).

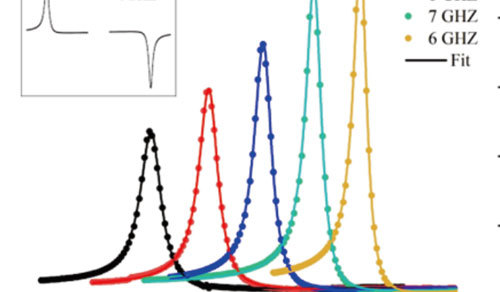

6. Temperature dependence study: By using Kerr microscope at different temperatures, the behavior of the magnetization process of Cr5Te8 nanosheets with temperature change was studied, and the tendency of Curie temperature (Curie temperature, TC) with sample thickness was found.

The low-temperature high-field micro-laser Kerr microscopic imaging system is a key tool for studying the magnetization process, magnetic domain structure and evolution, and magnetization reversal mechanism of Cr5Te8 nanosheets. It provides important experimental data and insights for in-depth understanding of the magnetic properties of materials and optimization of the performance of magnetoelectronic devices.

Two-dimensional ferromagnetic material magnetic properties characterization tool

Low-temperature strong-field micro-laser Kerr microscopic imaging system, which can combine high-resolution magnetic domain imaging with high-precision hysteresis loop scanning, normal temperature vertical strong magnetic field (1.4 T) and in-plane strong magnetic field (1 T);

• Sample temperature range: 5K-420 K, temperature stability ± 50 mK;

• Adjustable laser power;

• The magnet and sample holder are designed with slideways to facilitate the switching of different requirements tests;

• Reserved expansion interface, the magnetic field and low temperature environment platform, convenient compatible with other types of optical testing;

• Accurate detection of the magnetism of two-dimensional materials using differential amplification and phase-locking techniques;

• It is suitable for accurate magnetic measurement of spin devices or micron-sized materials. It is an expert scientific research equipment specially designed for the research of two-dimensional magnetic materials.

Micron-level spot and precise positioning in the sample area to be measured to achieve accurate detection of the hysteresis loop in the micro-area.

Comparison of test results of weak magnetic film

Results of Laser Kerr Microscopy

Test results of production line-level equipment of a top international company ↑ ↑

Research background:

Spin electronic devices with electron spin as the main information carrier have the advantages of small size, fast speed and low power consumption, and are strong competitors for information storage devices in the post-Moore era. In particular, the discovery of two-dimensional magnetic materials provides a material basis for the construction of new functional magnetoelectronic devices. Two-dimensional magnetic materials in the atomic layer thickness still maintain long-range magnetic order, with no surface dangling bonds, weak interlayer coupling, can be "atomic Lego" function heterogeneous integration, easy to control and other advantages, in the field of high-density magnetic information storage and spin electronics has important application prospects, become the international frontier hot spot. However, the two-dimensional magnetic materials have some difficulties, such as low Curie temperature, unstable environment, difficult to prepare large-scale and controllable, which greatly limit their application and development. Therefore, it is of great significance and value to explore new two-dimensional magnetic materials with better stability and realize their large-size and ultra-thin preparation by simple, economical and controllable methods for promoting the application of two-dimensional magnetic materials. In addition, the magnetic domain and its evolution of magnetic two-dimensional materials can provide an important reference for the performance optimization of related devices.

Conclusion:

Based on this, the team developed a simple, economical, scalable, hydrogen-modified chemical vapor deposition method to controllably synthesize sub-millimeter ultra-thin high-quality Cr5Te8 magnetic nanosheets. It is worth mentioning that the maximum lateral size of nanosheets can reach 450 μm, the air stability is good and the Curie temperature is high. In addition, through the direct observation of the magnetic domain evolution of Cr5Te8 nanosheets, the dominant role of domain wall nucleation in controlling the magnetization reversal process is revealed. Interestingly, the Cr5Te8 nanosheets exhibit non-monotonic magnetoresistance properties. This work has achieved an important breakthrough in the field of large-size two-dimensional magnetic materials prepared by CVD method, which provides an ideal platform for understanding and regulating magnetic-related properties on a two-dimensional scale, and is expected to promote the application and development of two-dimensional magnetic materials in spintronics devices.

Least News

Provide reliable equipment for advanced manufacturing, empowering technological innovation through precision measurement!!

Contact Information

Business Inquiries:+86-532-89267428/13335086685Manager Yao

Switchboard:+86-532-89269848

Company Address: 393 Songling Road, Laoshan District, Qingdao, Shandong Province, China

WeChat Official Account

Bilibili Account